Tel: +86-(0)769-87796906

Fax: +86-(0)769-83428065

Contact: travis lau

E-mail: travis.lau@infinity-machine.com

Website: www.infinity-machine.com

Factory Add: No.103 Building 4, Furong Industrial Center, Wangniudun Town, 523200, Dongguan City, China

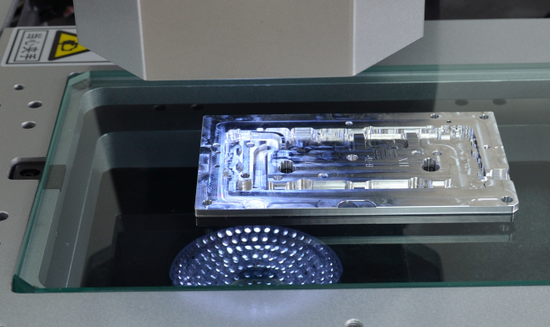

Name:Full-auto Image Measuring Instrument

Name: Full-auto Image Measuring Instrument

Model: IN-3020Q / IN-4030Q / IN-5040Q

Purpose:

Full-auto image measuring instrument is a cost-effective measuring instrument searched and developed by our company

aimed at market demands. It is specially designed with powerful independently researched and developed software

functions, and it is also easy for operation, suitable for size measurement on batch precision parts.

Applications:

It applies to industries of electronics, machinery, hardware, instrument, clocks and watches, light industry, war industry and

space flight and aviation, etc.

Functions:

Full-auto 2D geometry measurement, can realize basic 3D measurement, geometric tolerance assessment and reverse

engineering measurement of profile scanning.

Contact Us

+86-(0)769-83428065

NO.103 Building 4,No.27,Beihuan Road,Wangniudun Town,Dongguan City,Guangdong Province,China

东莞市万材智能设备有限公司 Copyright Since 1998-2016 粤ICP备08132298号 Powered by www.300.cn