Description Schemes:

1、 The main machine

1) The main machine adopts underneath type of oil cylinder, tensile space is above the main machine, compression and bending space is between the lower cross beam and working station.

2) Solid four-standard column and two-lead screw structure design, so the whole machine has strong stability.

3) Movable cross-beam is designed with unique clearance elimination mechanism, avoiding test error caused by cross-beam stress of B type machine.

4) There designs a sliding plate of 10mm between jaw and jaw splint, effectively extending service life of jaw splint.

5) Test space can be divided into three segments for adjustment according to length of specimen, the highest point is suitable for the use of peripheral equipment like high temperature furnace.

2、 Drive system

Lower cross beam lifting adopts hydraulic motor, chain, and lead screw pair drive to realize adjustment of tensile and compression space. No matter in the state of adjusting space or in the test process, it both reaches operation if zero clearance.

3、 Hydraulic system (table-type oil source)

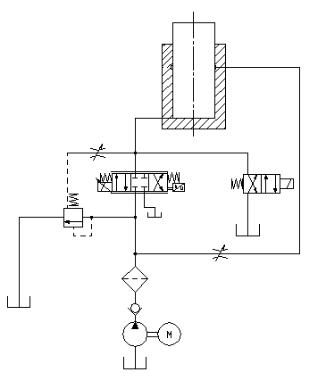

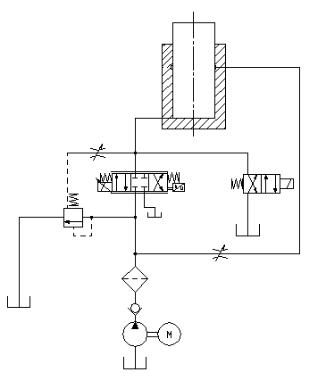

3.1 Hydraulic principle:

As shown in figure 2, it is load-adaptive meter in speed control system.

Hydraulic oil in the fuel tank enters into oil circuit when the motor drives the high-pressure gear pump, it flows through non-return valve, 10μhigh-pressure filter, differential pressure valve group and servo valve to enter into oil cylinder. The computer sends out signal to the servo motor, to control the mouth and direction of servo valve, so as to control the flow entering into the oil cylinder, realizing control of uniform-speed test force and displacement.

Figure 2: hydraulic principle

3.2 Features

1) It adopts imported high-pressure gear pump, with low noise and steady pressure.

2) It adopts integrated design for dynamic system and operating platform, easy to operate and saving test space at the same.

3) The surface is disposed with spraying plastics, so the appearance is nice.

Control system:

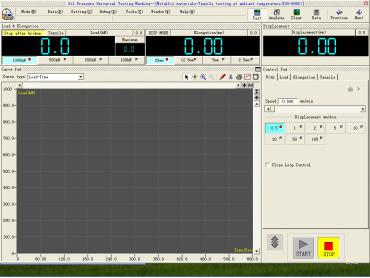

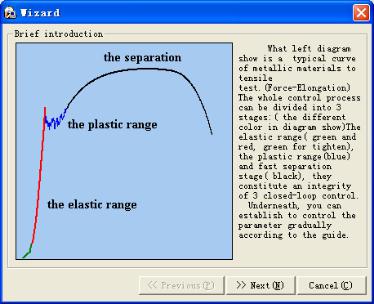

Full-digital measurement and closed loop control system has many advanced characteristics and technological innovation, mainly reflected in:

4.1 Realizing four kinds closed loop control system control of testing force, specimen deformation, cross-beam displacement and test process.

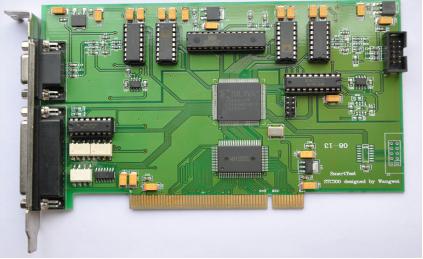

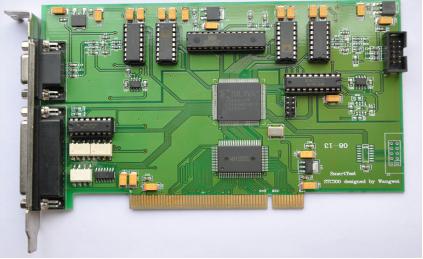

4.2 Data collecting system is composed of 4-path high precision 24-bit A/D shift channels, the maximum resolution ratio reaches 1/300000, the whole process is stepless.

4.3 It adopts original famous-brand integrated components like BB, AD and Xilinx, with full-digital Design.

4.4 It conforms to PCI bus standard, the microcomputer is automatic identification and installation for microcomputer, achieving “plug and test”.

4.5 There is no analogue element like potentiometer for electronic measurement system,guaranteeing interconvertibility and convenient for maintenance and replacement.