Tel: +86-(0)769-87796906

Fax: +86-(0)769-83428065

Contact: travis lau

E-mail: travis.lau@infinity-machine.com

Website: www.infinity-machine.com

Factory Add: No.103 Building 4, Furong Industrial Center, Wangniudun Town, 523200, Dongguan City, China

Name:600KN Capacity Universal Testing Machine

Name: 600KN Capacity Universal Testing Machine

Model: RS-8000A-600KN

Purpose:

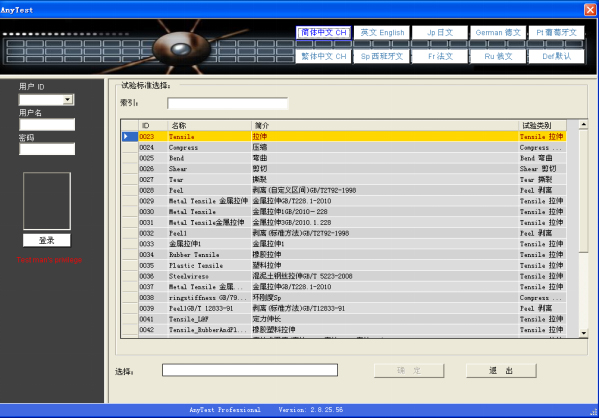

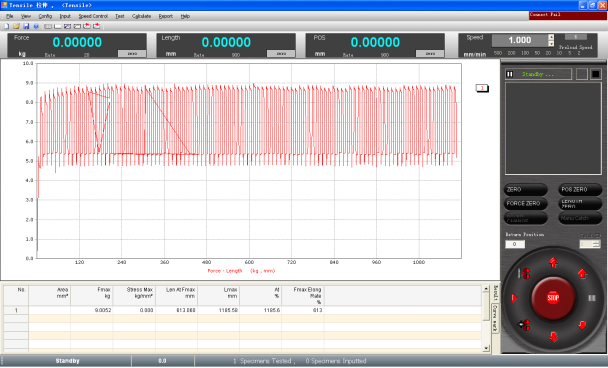

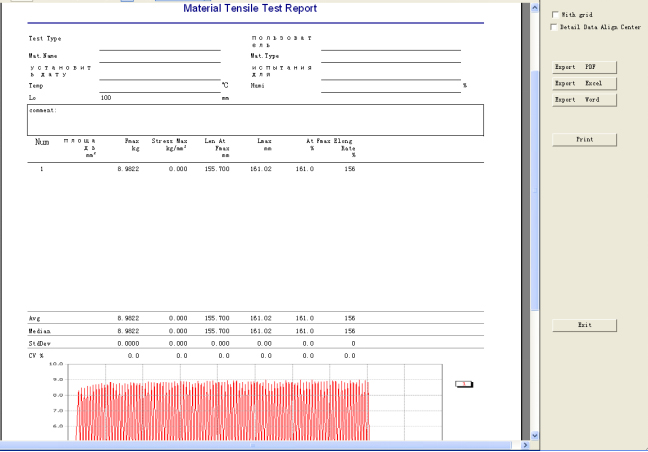

Controlled by a computer, the microcomputer-controlled electronic universal testing machine is widely applied in mechanical property tests of metal bar materials, metal pipes, metal sheet metal, metal profiled bars and composite materials and also applied in tensile, stretch, compression, stripping, shearing, avulsion, and bending tests equipped with special fixtures. Many data can be printed and graphic output can be compared according to different data with high control precision and user-friendly operation; adopting modular design, all kinds of accessory fittings has a complete range of articles and can be matched flexibly. The machine is mainly applied in tests of stretch, compression, bending and other mechanical properties and can also realize constant stress, creep deformation, loosening, axial direction, radial direction and other multi -circulation tests. Tensile strength, yield strength, elongation, specific elongation stress, specific stress elongation, elasticity modulus and other parameters can be automatically solved according to GB, JIS, ASTM, DIN and other standards.

Standard:

The testing machine is manufactured according to the standards including Electronic Universal Testing Machines (GB/T 16491-2008), General Requirements for Testing Machines (GB2611 -2007), Detection of Force Measuring System in Tensile and Compression Testing Machine, Technical Condition of Extensometer (JB6146-2007), and General Rules for the Examination of the Certificate of Manufacture Metrological Appliance (JJF1246-2010).

Testing Standard:

To meet Metallic Materials-Tensile Testing- Method of Test at Ambient Temperature (GB/T228 -2002), Metallic Materials- Bending Property Testing- Method of Test (GB/T14452-93) and other standard testing requirements.

Testable item:

Extensile test (standard configuration with clamps)

Stripping test (selective configuration with clamps)

Compression test (standard configuration with clamps)

Tearing test (selective configuration with clamps)

Bending test (selective configuration with clamps)

Shear test ((selective configuration with clamps)

Contact Us

+86-(0)769-83428065

NO.103 Building 4,No.27,Beihuan Road,Wangniudun Town,Dongguan City,Guangdong Province,China

东莞市万材智能设备有限公司 Copyright Since 1998-2016 粤ICP备08132298号 Powered by www.300.cn